Low And High Micro Pressure Transducer Sensor

|

Name |

Current/Voltage Pressure Transmitter |

Shell material |

304 stainless steel |

|

Core category |

Ceramic core, diffused silicon oil-filled core (optional) |

Pressure type |

Gauge pressure type, absolute pressure type or sealed gauge pressure type |

|

Range |

-100kpa...0~20kpa...100MPA (optional) |

Temperature compensation |

-10-70°C |

|

Precision |

0.25%FS, 0.5%FS, 1%FS (comprehensive error including non-linear repeatability hysteresis) |

Operating temperature |

-40-125℃ |

|

Safety overload |

2 times full scale pressure |

Limit overload |

3 times full scale pressure |

|

Output |

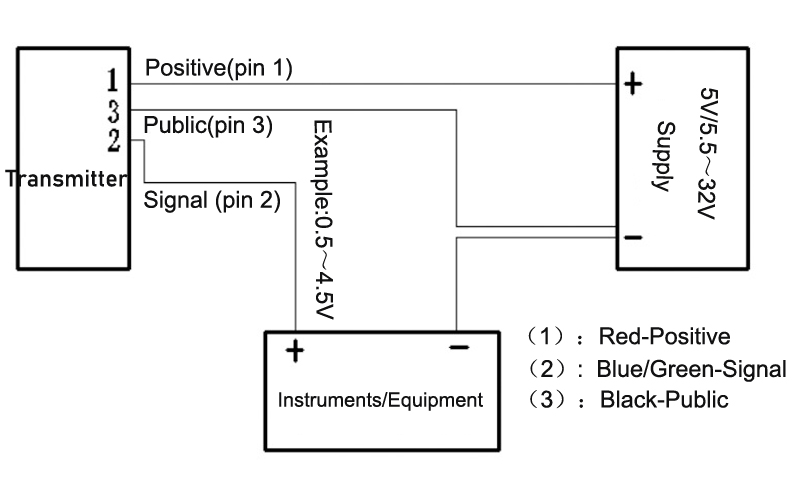

4~20mADC (two-wire system), 0~10mADC, 0~20mADC, 0~5VDC, 1~5VDC, 0.5-4.5V, 0~10VDC (three-wire system) |

Power supply |

8~32VDC |

|

Thread |

G1/4, 1/4NPT, R1/4, G1/8, G1/2, M20*1.5 (can be customized) |

Temperature drift |

Zero temperature drift: ≤±0.02%FS℃ Range temperature drift: ≤±0.02%FS℃ |

|

Long-term stability |

0.2%FS/year |

contact material |

304, 316L, fluorine rubber |

|

Electrical connections |

PACK plug |

Protection level |

IP65 |

|

Response time (10%~90%) |

≤2ms |

|

A)Before use, the equipment must be installed without pressure and power supply, The transmitter must be installed by a dedicated technician.

B) If you choose a diffused silicon sensor and use a diffused silicon oil-filled core, improper use may cause an explosion. To ensure safety, oxygen measurement is strictly prohibited.

C)This product is not explosion-proof. Use in explosion-proof areas will cause serious personal injury and material loss. If explosion-proof is required, please inform in advance.

D)It is forbidden to measure the medium that is incompatible with the material contacted by the transmitter. If the medium is special, please let us know and we will choose the right transmitter for you.

E)No modifications or changes can be made on the sensor.

F)Don't throw the sensor at will, please don't use brute force when installing the transmitter.

G)If the pressure port of the transmitter is upward or sideward when the transmitter is installed, make sure that no liquid flows in the equipment housing, otherwise moisture or dirt will block the atmospheric port near the electrical connection, and even cause equipment failure.

H) If the transmitter is installed in a harsh environment and may be damaged by lightning strikes or overvoltage, we recommend that users perform lightning protection and overvoltage protection between the distribution box or the power supply and the transmitter.

I)When measuring steam or other high-temperature media, be careful not to allow the temperature of the medium to exceed the operating temperature of the transmitter. If necessary, install a cooling device.

J)During installation, a pressure cut-off valve should be installed between the transmitter and the medium in order to repair and prevent the pressure tap from being blocked and affecting the measurement accuracy.

K) During the installation process, a wrench should be used to tighten the transmitter from the hexagonal nut at the bottom of the device to avoid directly rotating the upper part of the device and causing the connection line to be disconnected.

L)This product is a weak point device, and must be laid separately from the strong current cable when wiring.

M)Ensure that the power supply voltage meets the power supply requirements of the transmitter, and ensure that the high pressure of the pressure source is within the range of the transmitter.

N)In the process of pressure measurement, the pressure should be increased or relieved slowly to avoid instantaneous increase to high pressure or drop to low pressure. If there is instantaneous high pressure, please inform in advance.

O)When disassembling the transmitter, make sure that the pressure source and power supply have been disconnected from the transmitter to avoid accidents due to medium ejection.

P)Please don't disassemble it by yourself when using it, let alone touch the diaphragm, so as not to cause damage to the product.