High Accuracy Industrial Mechanical Pressure Transducer And Sensor

| Name | Current/Voltage Pressure Transmitter | Shell material | 304 stainless steel |

| Core category | Ceramic core, diffused silicon oil-filled core (optional) | Pressure type | Gauge pressure type, absolute pressure type or sealed gauge pressure type |

| Range | -100kpa...0~20kpa...100MPA (optional) | Temperature compensation | -10-70°C |

| Precision | 0.25%FS, 0.5%FS, 1%FS (comprehensive error including non-linear repeatability hysteresis) | Operating temperature | -40-125℃ |

| Safety overload | 2 times full scale pressure | Limit overload | 3 times full scale pressure |

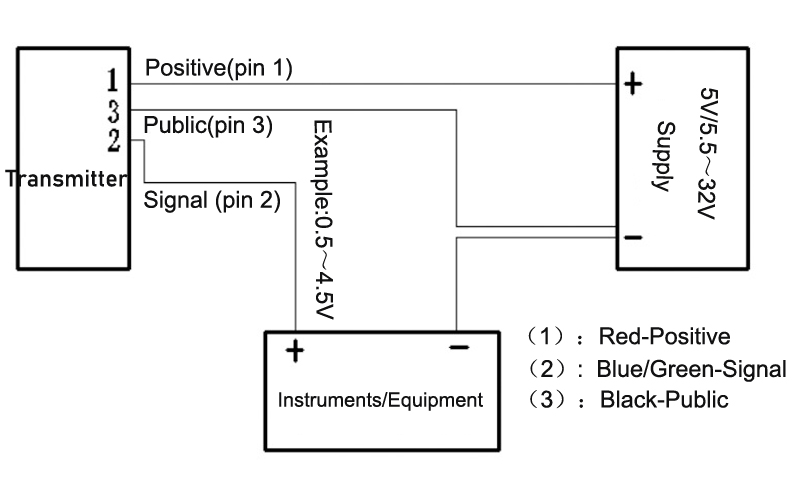

| Output | 4~20mADC (two-wire system), 0~10mADC, 0~20mADC, 0~5VDC, 1~5VDC, 0.5-4.5V, 0~10VDC (three-wire system) | Power supply | 8~32VDC |

| Thread | G1/4 (can be customized) | Temperature drift | Zero temperature drift: ≤±0.02%FS℃Range temperature drift: ≤±0.02%FS℃ |

| Long-term stability | 0.2%FS/year | contact material | 304, 316L, fluorine rubber |

| Electrical connections | Big Hessman, aviation plug, waterproof outlet, M12*1 | Protection level | IP65 |

1.Structure: The transmitter adopts stainless steel integral components, imported elastomer originals, combined with high-precision strain gauges and advanced patch technology, with high sensitivity, stable performance, and good impact resistance.

2.Measuring medium: Weakly corrosive liquid; weakly corrosive gas.

3.Uses: Widely used in pressure measurement and control of industrial equipment, water conservancy, chemical industry, medical treatment, electric power, air conditioning, diamond press, metallurgy, vehicle braking, building water supply, etc.

4.Such sensors are usually called: oil pressure sensor, oil pressure transmitter, hydraulic sensor, hydraulic transmitter, wind pressure sensor, wind pressure transmitter, air pressure sensor, air pressure transmitter, strain gauge pressure sensor, strain gauge Pressure transmitter, piezoresistive pressure sensor, piezoresistive pressure transmitter, positive and negative pressure sensor, positive and negative pressure transmitter, pipeline pressure sensor, pipeline pressure transmitter, etc.

A.Imported pressure sensing chip is adopted;

B.Advanced manufacturing technology, with zero, full-scale compensation and temperature compensation;

C.High precision and high stability amplifier IC;

D.Fully sealed welding structure, impact resistance, fatigue resistance and high reliability;

E.Diversified output signals (general analog output, digital RS485 / RS232 output, etc.);

F.Small structure, with a minimum outer diameter of 26mm;

G.The medium temperature can reach 800 ℃, and the connection mode is thread, flange, quick interface, etc;

H.Small structure, with a minimum outer diameter of 26mm;

M.The medium temperature can reach 800 ℃, and the connection mode is thread, flange, quick interface, etc;

1.Perform sanitary cleaning once a week to keep the transmitter and its accessories clean.

2.Check the pressure-taking pipeline and valve joints for leakage once a week. If there is any leakage, it should be dealt with as soon as possible.

3.Monthly check that the transmitter components are intact, no serious corrosion or damage; the nameplate and identification are clear and correct; the fasteners must not be loose, the connectors are in good contact, and the terminal wiring is firm.

4.Check the on-site measurement circuit once a month, including whether the input and output circuits are intact, whether the circuit is disconnected, short-circuited, and whether the insulation is reliable, etc.

5.Check the accuracy of the zero point and display value of the meter every month, and the zero point and display value of the transmitter are accurate and true.

6.Perform regular calibration according to the transmitter calibration cycle.

7.Periodically drain, drain or vent the transmitter.

8.The transmitter with isolation fluid in the source pipeline or measuring element is regularly filled with isolation fluid.

9.Regularly purge the pressure guiding tube of the easy-blocking medium.

10.When the transmitter is disabled for a long time, it should be turned off once.

11.When the transmitter is in operation, its housing must be well grounded. The transmitter used to protect the system should have measures to prevent power failure, short circuit, or output open circuit.

12.In the winter season, check that the instrument's source pipeline is well insulated and heat tracing, so as to avoid the source pipeline or the measuring element of the transmitter from being damaged by freezing.