Factory Free sample Sensitive Pressure Sensor - Water And Air Pressure Transducer And Sensor – Anxin

Factory Free sample Sensitive Pressure Sensor - Water And Air Pressure Transducer And Sensor – Anxin Detail:

| Name | Current/Voltage Pressure Transmitter | Shell material | 304 stainless steel |

| Core category | Ceramic core, diffused silicon oil-filled core (optional) | Pressure type | Gauge pressure type, absolute pressure type or sealed gauge pressure type |

| Range | -100kpa…0~20kpa…100MPA (optional) | Temperature compensation | -10-70°C |

| Precision | 0.25%FS, 0.5%FS, 1%FS (comprehensive error including non-linear repeatability hysteresis) | Operating temperature | -40-125℃ |

| Safety overload | 2 times full scale pressure | Limit overload | 3 times full scale pressure |

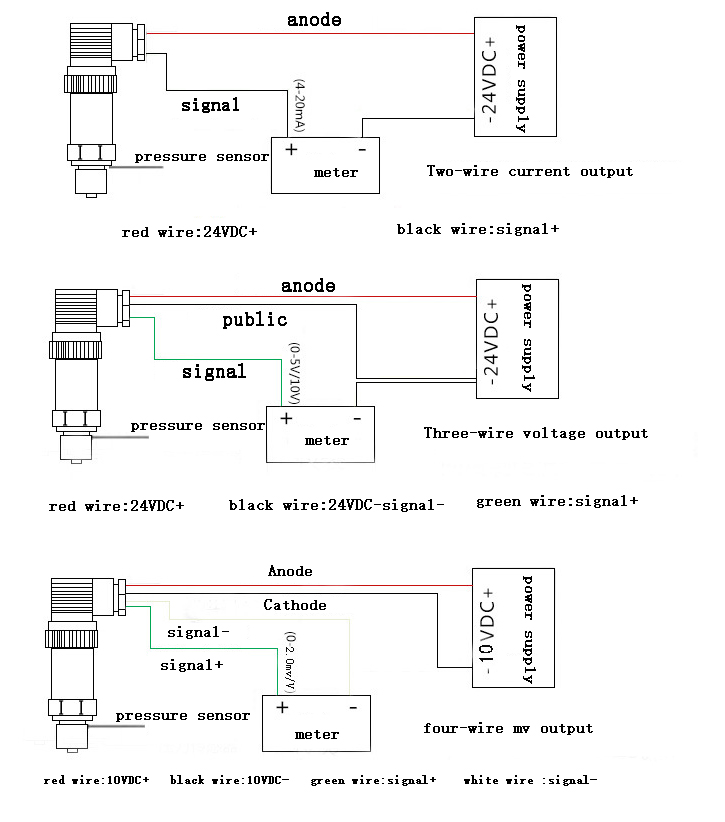

| Output | 4~20mADC (two-wire system), 0~10mADC, 0~20mADC, 0~5VDC, 1~5VDC, 0.5-4.5V, 0~10VDC (three-wire system) | Power supply | 8~32VDC |

| Thread | G1/4 (can be customized) | Temperature drift | Zero temperature drift: ≤±0.02%FS℃Range temperature drift: ≤±0.02%FS℃ |

| Long-term stability | 0.2%FS/year | Contact material | 304, 316L, fluorine rubber |

| Electrical connections | Big Hessman, aviation plug, waterproof outlet, M12*1 | Protection level | IP65 |

This series of sensors uses the advanced high-precision and high-stability diffused silicon core, equipped with ASIS high-performance amplifier circuit, after thousands of fatigue shocks, high and low temperature cycle aging and precise digital temperature compensation process, and then complete stainless steel sealing and welding (Laser welding) refined.

High-quality sensors, strict calibration process, and perfect assembly process ensure the excellent quality of the product.It is especially suitable for pressure measurement of hydraulic pressure, pneumatic pressure and other media, even for harsh environments such as sewage, steam, mildly corrosive, and gas measurement.

1.Small size, high precision, Cost-effective , high stability

2.-100kpa…0~20kpa…100MPA (optional)

3.A variety of signal output options, convenient for users to debug

4.Anti-lightning, anti-electromagnetic/radio frequency interference

5.Wide power supply range (5~40V)

Hydraulic pressure control

Building automation, constant pressure water supply

Metallurgy, machinery, environmental protection

Technical performance medical, vacuum equipment

Petrochemical pipeline pressure measurement

Automatic control system and test system

Product detail pictures:

Related Product Guide:

Well-run gear, qualified revenue workforce, and superior after-sales companies; We've been also a unified huge loved ones, anyone persist with the organization benefit "unification, determination, tolerance" for Factory Free sample Sensitive Pressure Sensor - Water And Air Pressure Transducer And Sensor – Anxin , The product will supply to all over the world, such as: Uruguay, Burundi, Finland, Our company considers that selling is not only to gain profit but also popularize the culture of our company to the world. So we are working hard to give you the wholehearted service and willing to give you the most competitive price in the market

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.