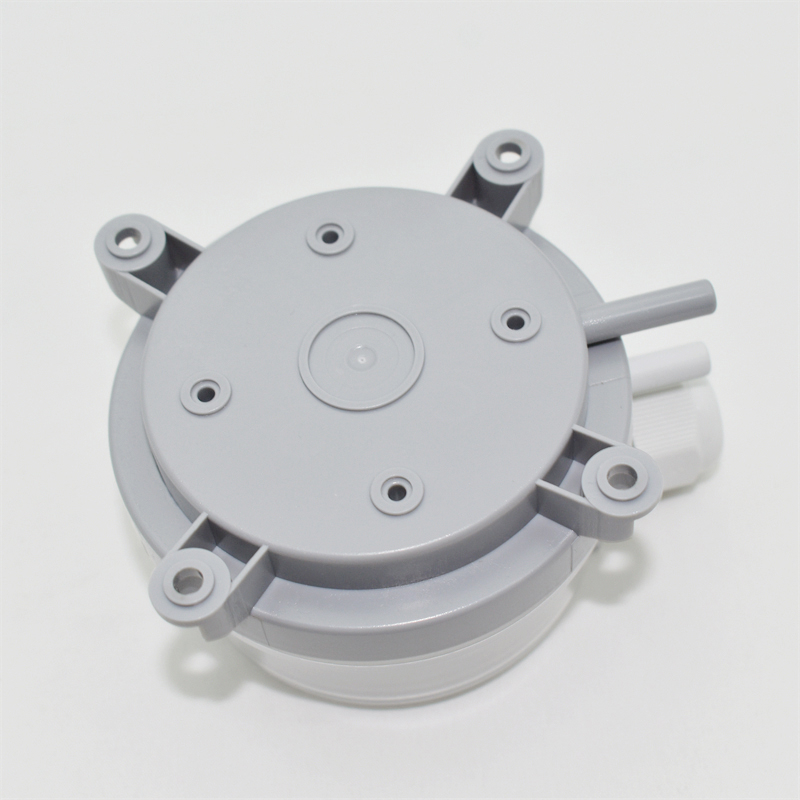

Differential Pressure Switch

| Electrical parameters | 5(2.5)A 125/250V |

| Pressure setting | 20pa~5000pa |

| Applicable pressure | Positive or negative pressure |

| Contact resistance | ≤50mΩ |

| Maximum breakage pressure | 10kpa |

| Operating temperature | -20℃~85℃ |

| Connection size | Diameter 6mm |

| Insulation resistance | 500V-DC-lasted 1min,≥5MΩ |

| Control Method | Open and close method |

| Electric strength | 500V---- lasted 1min, no abnormality |

| Installation method | Recommended for vertical installation |

| Applicable medium | Non-hazardous gas, water, oil, liquid |

| Protection level | IP65 |

| Wiring | Soldering, socket terminal, crimping screw |

| Switch function | Normally open (open in free state), normally closed (closed in free state) |

| model | Pressure range | Differential pressure/return value | Setting error | Optional accessories |

| AX03-20 | 20-200pa | 10pa | ±15% | 1 meter trachea 2 connectors

2 sets of sockets |

| AX03-30 | 30-300pa | 10pa | ±15% | |

| AX03-40 | 40-400pa | 20pa | ±15% | |

| AX03-50 | 50-500pa | 20pa | ±15% | |

| AX03-100 | 100-1000pa | 50pa | ±15% | Trachea 1.2 meters 2 connectors

3 sets of sockets |

| AX03-200 | 200-1000pa | 100pa | ±10% | |

| AX03-500 | 500-2500pa | 150pa | ±10% | |

| AX03-1000 | 1000-5000pa | 200pa | ±10% |

The differential pressure switch is a special pressure control switch, which is based on the mutual pressure difference between various components, and transmits information through electrical signals to control the closing or opening of the switch.The valve body of the differential pressure switch and the travel switch are assembled on a bottom plate. Under the action of pressure, the grease enters the right cavity of the differential pressure switch valve body piston from the main pipe B, and the main pipe A is unloaded.Once the pressure difference between the two main pipelines reaches the set value, the piston overcomes the spring force in the left cavity and moves to the left, and pushes the travel switch to close the contact, and sends a pulse signal to the system electric control box to order the reversing valve to change direction.At this time, the main pipe A is compressed, and B is unloaded. The piston is centered under the action of the spring in the two-end cavity, the stroke switch contacts 1 and 2 are disconnected, and the contact bridge is in the neutral position.

The system starts the second cycle. Once the pressure difference between the main pipeline A and B reaches the set value again, the piston moves to the right, the stroke switch contacts 3 and 4 are closed, and the pulse signal again causes the reversing valve in the system to change direction. Start the next cycle of work.

The differential pressure switch can be widely used in large, medium and small air-cooled or water-cooled chillers using plate heat exchangers, tube heat exchangers and shell and tube heat exchangers for water flow control and water pump and water filter status monitoring .It is also used in gas detection, non-corrosive media, absolute pressure measurement, gauge pressure, and is widely used in air conditioning and clean room, fan and filter blowing control, fluid and liquid level control.

The application of the differential pressure switch in the HVAC system is mainly controlled according to the resistance and flow curve of the HVAC equipment, the water side heat exchanger in the HVAC (tube-in-tube type, shell-and-tube type, tube-plate type and commonly used plate heat exchanger) , Water filters, valves and pumps have their pressure drop and flow performance curves. As long as the measured pressure difference on both sides of the pressure difference switch is compared with the preset value, the flow can be accurately controlled.